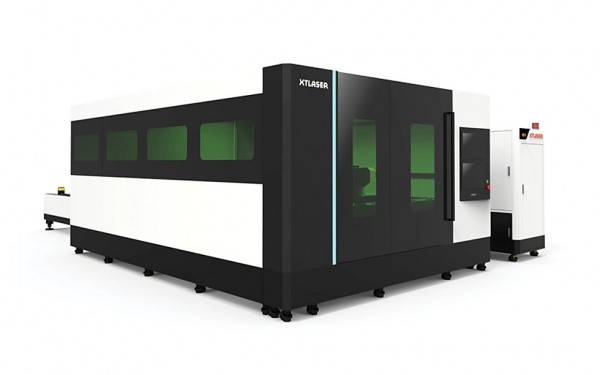

CUTTING PRECISION LASER XTC-FS1530 FIBRE

Laser-cutting is characterised by a higher concentration of energy resulting from shorter wavelengths of light, which translates into both a high cutting precision and energy saving. The laser enables the cutting, marking and engraving of details.

- cutting in carbon steel, stainless steel, aluminium, copper and brass

- specialised nesting software enabling fast simulation and calculation of the cutting process and material saving

- working field: 1,500 x 3,000 mm

- a system of interchangeable tables speeds up work

- cutting precision

- repeatability of cutting elements

- x 10For thin sheets of up to 5 mm, the cost of cutting some part can be up to ten times less.

- 30%The laser has a higher energy efficiency (of up to 30%) compared to CO2 cutting, where the efficiency reaches a maximum of 5%.

-

dwg

dxf, cdrA wide range of files. We support a wide range of specialised programs for graphic designers, engineers and architects, which enables file conversion between programs.

LASER XTC-FS1530 Fibre

In our machine park, we have an XTC-FS1530 Fibre laser for cutting sheet metal. It is equipped with a Raytools Autofocus 2D cutting head and a 1kW Raycus resonator. All structural subunits, including laser resonators and CNC control, are supplied by world-class manufacturers and manufactured similarly to those developed by XT LASER. A CNC controller with CYPCUT software and the NESTING function, which allows automatic optimisation of project placement on the material.

Laser-Cutting

Laser-Cutting Water-cutting

Water-cutting Sheet

Sheet Welding

Welding Railings

Railings Blasting

Blasting Pulverulent

Pulverulent Advertisement

Advertisement Storage

Storage